1997ThunderbirdLXV6

Seasoned Veteran Poster

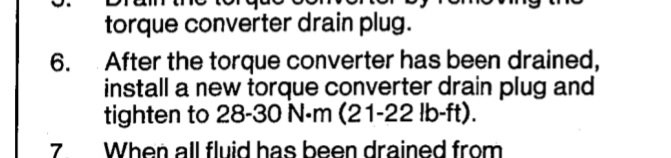

The Ford workshop manual states that after draining the torque converter, you should replace the plug with a new one.

Why?

If for argument sake I wanted to obey the manual, the stated part number is 87650S - which is obsolete.

Ford does produce a torque converter drain plug for Mustang and Panther from 2001 onward according to my local dealership Parts guy, part number 391346S. That's odd because...wasn't it around that time that the plug was eliminated altogether?

They also didn't see anything indicating that the new part number superseded the old one.

So does anyone have a current part number? Are these two plugs in fact identical? Or do you just reuse your existing plug?

Why?

If for argument sake I wanted to obey the manual, the stated part number is 87650S - which is obsolete.

Ford does produce a torque converter drain plug for Mustang and Panther from 2001 onward according to my local dealership Parts guy, part number 391346S. That's odd because...wasn't it around that time that the plug was eliminated altogether?

They also didn't see anything indicating that the new part number superseded the old one.

So does anyone have a current part number? Are these two plugs in fact identical? Or do you just reuse your existing plug?