No progress on the brace, was busy helping a busy this weekend. But the grind continues!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SHOCK tower bar interest

- Thread starter Chingon1

- Start date

CDsDontBurn

3rd Gear Poster

.

^ My "follow thread" dot.

^ My "follow thread" dot.

Ordered tube today, waiting for them to get it ready for pick up. It’s A513 DOM.

define planted?

I feel like my car feels more planted when my moonroof is in the tilt position at speed

I feel like my car feels more planted when my moonroof is in the tilt position at speed

@XR7-4.6 I feel like on bumpy roads if one wheel hits a bump the shock load isn’t transferred to the opposite side as much. It’s still there but not as much. These are the same roads same driving habits.

Once I get the braces done, I’d gladly send any one of you guys my stock cheapy brace so one of y’all can try it out and let me know what you think.

Once I get the braces done, I’d gladly send any one of you guys my stock cheapy brace so one of y’all can try it out and let me know what you think.

dDUBb

5th Gear Poster

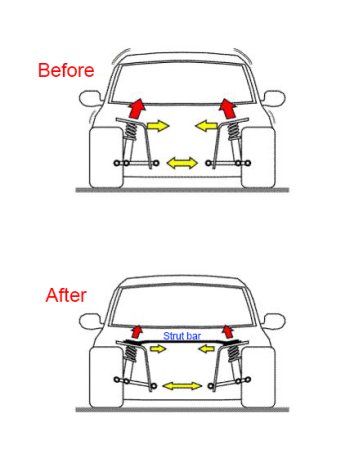

First, lets go back to the title of this thread - Strut Tower Brace.

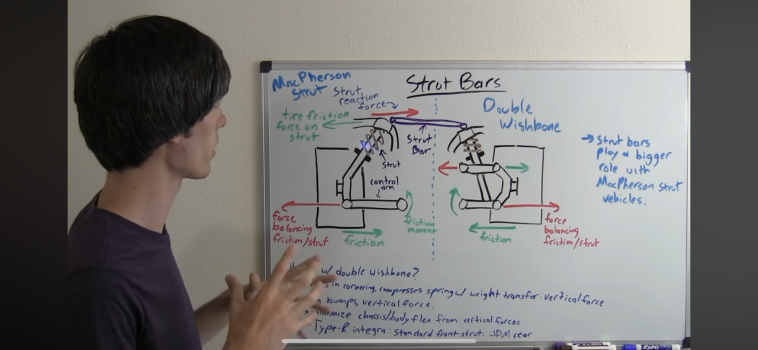

These cars don't have struts, apparently .. the difference between a Macpherson strut and a spring / shock combo is the load bearing on the chassis .. the short arm / long arm setup we use does not transmit loads the same way - in other words, by tying the Struts together, the strut tower brace becomes an additional suspension component more so than a structural one. The strut tower brace will help with the distribution. On vehicles that actually use struts.

In this case, a shock tower brace .. is more in line with an additional chassis brace to reduce any flex the body may absorb. The amount of flex may be compounded by having stiffer springs, bushings and anti sway bars - this may provide a small amount of body rigidity where the body would flex a greater distance - hard cornering .. not bumpy roads.

That being said, any time you reinforce a component, the flex will be transmitted elsewhere, so without having a full set of subfrale connectors, I would anticipate any body flex to mitigate to the firewall area.

1.25" ID DOM as a material is more along the lines of rollcage components - it would not be used for the roll cage structure itself except in amateur class racing, but it would be strong enough to be considered for a bracket to mount something to the cage.

These cars don't have struts, apparently .. the difference between a Macpherson strut and a spring / shock combo is the load bearing on the chassis .. the short arm / long arm setup we use does not transmit loads the same way - in other words, by tying the Struts together, the strut tower brace becomes an additional suspension component more so than a structural one. The strut tower brace will help with the distribution. On vehicles that actually use struts.

In this case, a shock tower brace .. is more in line with an additional chassis brace to reduce any flex the body may absorb. The amount of flex may be compounded by having stiffer springs, bushings and anti sway bars - this may provide a small amount of body rigidity where the body would flex a greater distance - hard cornering .. not bumpy roads.

That being said, any time you reinforce a component, the flex will be transmitted elsewhere, so without having a full set of subfrale connectors, I would anticipate any body flex to mitigate to the firewall area.

1.25" ID DOM as a material is more along the lines of rollcage components - it would not be used for the roll cage structure itself except in amateur class racing, but it would be strong enough to be considered for a bracket to mount something to the cage.

@XR7-4.6 I feel like on bumpy roads if one wheel hits a bump the shock load isn’t transferred to the opposite side as much. It’s still there but not as much. These are the same roads same driving habits.

Once I get the braces done, I’d gladly send any one of you guys my stock cheapy brace so one of y’all can try it out and let me know what you think.

It sounds awfully like what you’re describing is bumpsteer. Think about that for a second, what typically causes that is the tie rods and LCAs changing lengths relative to each other through travel. If the shock towers were moving like blades of grass in the breeze over pumps the UCA would move inboard and gain camber, but the LCA and tie rod would remain in the same relationship with each other, there’s no effect on bumpsteer.

Besides which why would the STB prevent load transfer to the other side, whatever load that is? That’s the whole purpose of it, to distribute the shock load exerted against the one tower to the other

It’s a nice offer, but one that requires drilling holes into virgin body structure that won’t plug themselves when it doesn’t pass the Pepsi challenge. Besides which a skeptic will not want it to work as much as an optimist would want it to work because STBs are “cool”. If you want a STB you want a STB, just like a rear wing or a CAI or something else of dubious value.

Last edited:

M

In this case, a shock tower brace .. is more in line with an additional chassis brace to reduce any flex the body may absorb. The amount of flex may be compounded by having stiffer springs, bushings and anti sway bars - this may provide a small amount of body rigidity where the body would flex a greater distance - hard cornering .. not bumpy roads.

I’m not an engineer by any means, so excuse my ignorance. Since we don’t have shocks and have struts instead, the force loads aren’t the same??

the force still has to go somewhere, does the force load transmit to the body via the upper control and lower control arms? In that case wouldn’t a strut tower bar help with keeping those towers together, since the control arms are taking the abuse of the roads??

It sounds awfully like what you’re describing is bumpsteer. Think about that for a second, what typically causes that is the tie rods and LCAs changing lengths relative to each other through travel. If the shock towers were moving like blades of grass in the breeze over pumps the UCA would move inboard and gain camber, but the LCA and tie rod would remain in the same relationship with each other, there’s no effect on bumpsteer.

Besides which why would the STB prevent load transfer to the other side, whatever load that is? That’s the whole purpose of it, to distribute the shock load exerted against the one tower to the other

@XR7-4.6 makes sense, would a bumpsteer kit fix this?? I know the mustang guys have kits on hand.

Also that is the goal of the strut tower bar? To share the load associated with strut towers?? That’s what I’m thinking the brace was for??

Inform me sensei!

I’m not an engineer by any means, so excuse my ignorance. Since we don’t have shocks and have struts instead, the force loads aren’t the same??

the force still has to go somewhere, does the force load transmit to the body via the upper control and lower control arms? In that case wouldn’t a strut tower bar help with keeping those towers together, since the control arms are taking the abuse of the roads??

We have shocks! The only struts attached to the towers of these cars are the hood struts lol

The big difference between strut and shock tower loads is shock towers spread out their load more evenly within the tower (UCA pivot and shock mount, rather than the single strut mount) and SLA systems have the shock mounted much lower than the strut. MN12s obviously have big bulky shock towers, but notice the actual top of the shock is inches down from the top of the tower, strut cars have the mount at the very top of the tower, practically against the hood, exerting more leverage via the tower against the frame rail most of the load is transferred to. Struts cars also have taller towers in and of themselves, the MN12s low hoodline is a direct result of the usage of SLA, whereas Macpherson struts mount the bottom of the strut to the top of the spindle, meaning a full length shock body needs to fit between it and the top of the tower, that makes for taller shock towers and even more leverage acted against the towers/frame rails.

The force is distributed through the unibody structure, the towers, the frame rails, the upper rails the torque boxes and the cowl structure. Not all cars are created equal, some are flimsier than others and I can assure you despite your assumptions the MN12 front shock tower structure is about as strong as anything out there even by today's standards if it hasn't rusted away, the overall chassis leaves something to be desired, but I couldn't think of a front clip in less need of additional bracing than one of these. Shock/strut tower bars came into vogue when automakers decided to campaign compact sedans in hillclimb events in the 1960s, like the Falcon or early Mustang, these cars were legitimately flimsy in their unibody structure, a STB and the fabled "monte carlo bar" were band-aids before the automakers used computer modeling ffor structural analysis, since then STBs have largely been a decorative item because they're imprinted in our minds as something related to high performance, Even on cars that do have struts where the loads are more focused the effectiveness of a STB is miniscule compared to the olden days.

@XR7-4.6 makes sense, would a bumpsteer kit fix this?? I know the mustang guys have kits on hand.

Also that is the goal of the strut tower bar? To share the load associated with strut towers?? That’s what I’m thinking the brace was for??

Inform me sensei!View attachment 2020View attachment 2021

You've mentioned before you're running 275s in front, that's the problem. There's really no getting away from it with a bumpsteer kit, and generally speaking the bumpsteer kits meant for Mustangs exist because the Fox spindles have an odd placement for the tie rods that gets worse with lowering, MN12s don't really have that since the tie rods and LCA are pretty much mirroring each other throughout travel.

In essence yes, but therein lies a flaw in the logic that has always driven me nuts with STBs; If the towers flex from load, why would linking them together improve things? Would not the loaded tower transfer that load through the STB and then to the other tower, and simply deflect the other tower like one big parallelogram? Shouldn't the purpose of bracing something that's deflecting to brace it against something that isn't deflecting?

Last edited:

Short story here... My 96 Tbird I had years ago developed some serious rust issues. The reason I got rid of it was because the passenger front shock tower rusted out. It was to the point that it looked like it was about to shoot through the hood. I found out by opening the hood to check the oil. It still drove perfectly fine and had no noticeable handling difference.

Great to see you making something for these cars though... TBH you would probably get a lot more interest on Facebook selling them. I imagine most the people here myself included believe they are just another bolt on that isn't going to do much of anything

Great to see you making something for these cars though... TBH you would probably get a lot more interest on Facebook selling them. I imagine most the people here myself included believe they are just another bolt on that isn't going to do much of anything

@XR7-4.6 this is a new s550, I noticed the torque boxes have this buldge on them I’m assuming it’s like factory bracing built into the car? To better help transfer those loads you say that go through the whole front?

“In essence yes, but therein lies a flaw in the logic that has always driven me nuts with STBs; If the towers flex from load, why would linking them together improve things? Would not the loaded tower transfer that load through the STB and then to the other tower, and simply deflect the other tower like one big parallelogram? Shouldn't the purpose of bracing something that's deflecting to brace it against something that isn't deflecting?”

Would the fix for this be an x brace connecting both shock towers instead of the bar? Obviously it would never work the engine is in the way. Just trying to picture what you’re saying.

Let’s say driving on a road, the right side tire hits a bump. You said that you want to brace against something that isn’t deflecting, wouldn’t the bar in this situation connect to the opposite side stock tower that hasn’t felt the bump? Since that tower hasn’t been deflecting due to hitting the same bump, it helps stabilize the other side since it’s not deflecting and solid?

I also have other ideas I wanted to run by you guys as well, pretty sure you don’t think they would work either but I’d like to try and see/feel for myself

“In essence yes, but therein lies a flaw in the logic that has always driven me nuts with STBs; If the towers flex from load, why would linking them together improve things? Would not the loaded tower transfer that load through the STB and then to the other tower, and simply deflect the other tower like one big parallelogram? Shouldn't the purpose of bracing something that's deflecting to brace it against something that isn't deflecting?”

Would the fix for this be an x brace connecting both shock towers instead of the bar? Obviously it would never work the engine is in the way. Just trying to picture what you’re saying.

Let’s say driving on a road, the right side tire hits a bump. You said that you want to brace against something that isn’t deflecting, wouldn’t the bar in this situation connect to the opposite side stock tower that hasn’t felt the bump? Since that tower hasn’t been deflecting due to hitting the same bump, it helps stabilize the other side since it’s not deflecting and solid?

I also have other ideas I wanted to run by you guys as well, pretty sure you don’t think they would work either but I’d like to try and see/feel for myself

Last edited:

Thank you! I see people asking about these bars here and there and id be cool to help out the communityShort story here... My 96 Tbird I had years ago developed some serious rust issues. The reason I got rid of it was because the passenger front shock tower rusted out. It was to the point that it looked like it was about to shoot through the hood. I found out by opening the hood to check the oil. It still drove perfectly fine and had no noticeable handling difference.

Great to see you making something for these cars though... TBH you would probably get a lot more interest on Facebook selling them. I imagine most the people here myself included believe they are just another bolt on that isn't going to do much of anything

@XR7-4.6 this is a new s550, I noticed the torque boxes have this buldge on them I’m assuming it’s like factory bracing built into the car? To better help transfer those loads you say that go through the whole front?

Could be reenforcement, could also be a safety feature to deflect the tire from going into the passenger compartment to help pass the tough NHTSA small overlap tests, deflecting the wheel away directly from the passenger compartment. The S550 was very likely developed to pass this test, which just about every production car (even the really stiff ones that previously had 5 star ratings) were performing miserably in this test, as the barrier essentially misses the frame rail/crumple zone, smashing the tire/wheel hard and square into the firewall

That's the thing when looking at these sorts of things, not every structural difference you observe is about making the car perform better.

View attachment 2022

“In essence yes, but therein lies a flaw in the logic that has always driven me nuts with STBs; If the towers flex from load, why would linking them together improve things? Would not the loaded tower transfer that load through the STB and then to the other tower, and simply deflect the other tower like one big parallelogram? Shouldn't the purpose of bracing something that's deflecting to brace it against something that isn't deflecting?”

Would the fix for this be an x brace connecting both shock towers instead of the bar? Obviously it would never work the engine is in the way. Just trying to picture what you’re saying.

A fix is to say there's a problem, and there isn't. But for the sake of argument, sure if you crisscrossed beams through every open compartment of an automobile, it will indeed be stronger and denser, it's just not very practical and the necessity for such is really not there when the structure adequately handles shock loads. Its the same concept as a full roll cage in an interior, but the stiffening effect isn't the reason they're there, it's for a racecar driver's safety, with the stiffening aspect a happy side effect. However if human beings weren't made of fragile bits of flesh and bone and life had a convenient reset button no driver would bother with a FIA spec roll cage no matter how much more rigid it makes the chassis, lighter is better.

I'm saying IF the right shock tower deflects in any measurable way, and IF the shock tower bar were 100% rigid with no inherent deflection within itself, it seems to me whatever structural deficiency is allowing the right tower to deflect inward would simply push the rigid bar and deflect the left tower outward.Let’s say driving on a road, the right side tire hits a bump. You said that you want to brace against something that isn’t deflecting, wouldn’t the bar in this situation connect to the opposite side stock tower that hasn’t felt the bump? Since that tower hasn’t been deflecting due to hitting the same bump, it helps stabilize the other side since it’s not deflecting and solid?

I also have other ideas I wanted to run by you guys as well, pretty sure you don’t think they would work either but I’d like to try and see/feel for myself

This is a hypothetical best case scenario favoring the bar btw, break it down to the idea that the shock towers are the same amount of deficient but the bar isn't perfectly rigid, the right tower will deflect, the tower bar will deflect, doing nothing. Break it down to the towers are not deficient and the tower bar does nothing at all.

BTW IF the towers deflect in our chassis, you'd literally be able to see it, the towers are welded to the fender rails which are bolted to the fenders, if there were inward deflection in the left tower the gap right in front of you between the hood and fender would decrease with heavy shock load.

Last edited:

@XR7-4.6 thank you for the detailed response honestly, I really appreciate the effort you put into replying. And I totally understand, I know our car is getting older and just isn’t up to par in terms of rigidity compared to new cars. But I know with some effort it could be helped some.

I’m still waiting on the tube to pick up and take to the fabricator. I really wish I could mount the bar directly to the top of the shock tower without the need to drill holes on the tower, but like I said I have coil overs and I know most people have stock shocks which have that stub coming up and wouldn’t be compatible with mine.

I really want to start another thread and share some ideas I have to help this chassis. And hear your feedback.

I’m still waiting on the tube to pick up and take to the fabricator. I really wish I could mount the bar directly to the top of the shock tower without the need to drill holes on the tower, but like I said I have coil overs and I know most people have stock shocks which have that stub coming up and wouldn’t be compatible with mine.

I really want to start another thread and share some ideas I have to help this chassis. And hear your feedback.

Tying the shock absorber stubs together would do less than nothing, there's sound theory and valid applications for tower bars in certain applications but the key in their functionality is that they're mounted directly to unibody structure, not the shock absorber threads. The shock absorbers on our cars have no effect on suspension geometry whatsoever, actual struts do, but even then at the point of the stub it will have some degree of isolation between it and the upper mount that fixes it to the towers, none of that bracing effect will be transferred into the unibody with that isolation, the bar will just be along for the ride.@XR7-4.6 thank you for the detailed response honestly, I really appreciate the effort you put into replying. And I totally understand, I know our car is getting older and just isn’t up to par in terms of rigidity compared to new cars. But I know with some effort it could be helped some.

I’m still waiting on the tube to pick up and take to the fabricator. I really wish I could mount the bar directly to the top of the shock tower without the need to drill holes on the tower, but like I said I have coil overs and I know most people have stock shocks which have that stub coming up and wouldn’t be compatible with mine.

I really want to start another thread and share some ideas I have to help this chassis. And hear your feedback.

If you wanted to make a true drill free bolt on bar you shouldn't use the one stub coming up off the shock absorber but instead use the three studs coming up from the shock/spring mount, which your coil-overs still utilize. That's at least attached to the unibody.

@XR7-4.6 yea sorry that’s what I meant, mounting it to those bolts, for coil over guys we can just buy longer bolts and secure it easy, but shock guys i don’t know how far up the stock bolts come up and that middle piece would be in the way.

I also have a picture I snagged of TCCOA showing a ruff idea of what would be possible.

I also have a picture I snagged of TCCOA showing a ruff idea of what would be possible.

@XR7-4.6 yea sorry that’s what I meant, mounting it to those bolts, for coil over guys we can just buy longer bolts and secure it easy, but shock guys i don’t know how far up the stock bolts come up and that middle piece would be in the way.

I also have a picture I snagged of TCCOA showing a ruff idea of what would be possible.

View attachment 2062View attachment 2063

The studs can be driven out with longer nut bolts used in place. The OEM upper shock mounts have longer studs that would probably be adequate in length as is, some aftermarket ones have shorter studs, which make fitting the SC ARC covers impossible.

Alright, for these first 5 since the plates have been made I’m gonna do them like my brace. The next ones will hopefully bolt up to the top of the shock mount. Thanks @XR7-4.6

I’ve weighed the STB and it’s about 5-7lbs for anybody wondering the weight. The bar I got is a513, recently found some a500 for cheaper but needs to get shipped in.

I’ve weighed the STB and it’s about 5-7lbs for anybody wondering the weight. The bar I got is a513, recently found some a500 for cheaper but needs to get shipped in.

- Joined

- Sep 12, 2023

- Messages

- 1,086

- Location

- Charlotte, NC

- Vehicle Details

- '95 Thunderbird with '18 TF 5.3L - SVO Engine

Alright, for these first 5 since the plates have been made I’m gonna do them like my brace. The next ones will hopefully bolt up to the top of the shock mount. Thanks @XR7-4.6

I’ve weighed the STB and it’s about 5-7lbs for anybody wondering the weight.

As we've beat the Strut/Shock difference to death I just changed the thread title to accurately reflect what MN12's have and put everyone's mind at ease.

I know, certain things like that drive me crazy too. It's like nails on a chalkboard.

Thank you!

No updates yet broskies, holiday season is at hand and I’m not pressing the issue.

But I do have some further bracing questions in key areas. Such as the KMember, I’m not sure but I’m assuming that skimpy bar bolted together on the ends is supposed to connect them??

This is what I had in mind, the whole front of the K

Pretty much the k member engulfs the rack n pinion, which to me looks like it EASILY flexes since there no support on the outer bushing side where that cheapy stock brace bolts too.

While working on my buds wrx Sti I noticed their rack is also built into the kmember like ours. What really caught my attention was that middle plate that connects both ends of the kmember together. Here’s a picture. Would something like this do anything to our cars??

Does the Kmember have anything to do with the rigidity of the unibody itself? In other words would a stiffer Kmember/IRS cradle aid in torsional rigidity??

But I do have some further bracing questions in key areas. Such as the KMember, I’m not sure but I’m assuming that skimpy bar bolted together on the ends is supposed to connect them??

This is what I had in mind, the whole front of the K

Pretty much the k member engulfs the rack n pinion, which to me looks like it EASILY flexes since there no support on the outer bushing side where that cheapy stock brace bolts too.

While working on my buds wrx Sti I noticed their rack is also built into the kmember like ours. What really caught my attention was that middle plate that connects both ends of the kmember together. Here’s a picture. Would something like this do anything to our cars??

Does the Kmember have anything to do with the rigidity of the unibody itself? In other words would a stiffer Kmember/IRS cradle aid in torsional rigidity??

Attachments

Last edited:

Wile E. Coyote

3rd Gear Poster

- Joined

- Sep 21, 2023

- Messages

- 186

- Location

- NJ

- Vehicle Details

- 1996 Tbird LX, SVO blown 4.6 // 1990 Tbird SC Drift missile, OHV 5.0

Just get the tubular k member if you want to go that far with bracing things.

Wile E. Coyote

3rd Gear Poster

- Joined

- Sep 21, 2023

- Messages

- 186

- Location

- NJ

- Vehicle Details

- 1996 Tbird LX, SVO blown 4.6 // 1990 Tbird SC Drift missile, OHV 5.0

You're kidding, right?

@Wile E. Coyote legit question

You can guess my opinion lol