Might be an odd question, but does anyone have a lead on GT40 intake flanges? Looking to make an intake and I don't wanna have to mess with 1/4in plate making a flange.

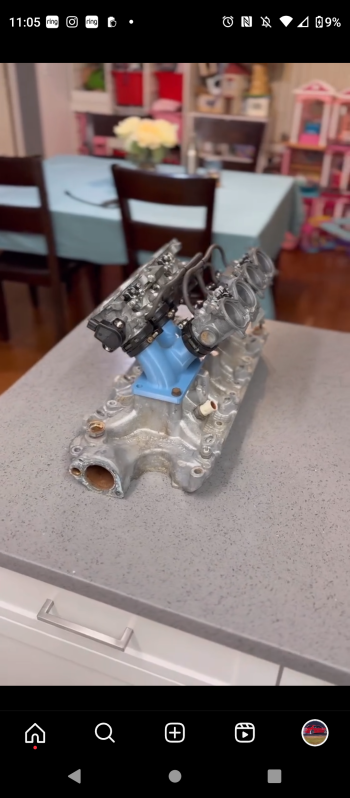

For the upper intake? You could probably just use a spacer like this to build from

Loading…

www.amazon.com